UNION-StruCell®

In Stock & Custom Orders

| Availability: | |

|---|---|

| Quantity: | |

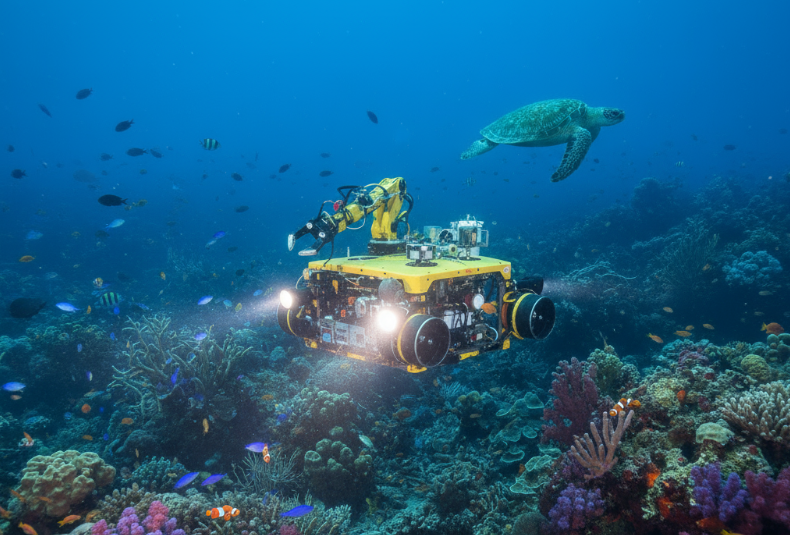

Our rov buoyancy foam is engineered to deliver neutral buoyancy in deep-water operations, with densities optimized for depths up to 6,000 meters. It features a closed-cell structure that minimizes water ingress (absorption <0.5% per ASTM D2842), ensuring consistent performance without buoyancy loss over time. As a leading PVC foam supplier, we offer CNC machining for complex geometries, reducing assembly time and material waste in your production line.

We provide custom-machined marine structural foam components as pre-cut modules, secured for safe shipping and easy integration:

High Buoyancy and Low Density: Densities from 45–250 kg/m³ allow precise buoyancy control, ideal for ROVs where every gram affects energy efficiency and payload capacity.

Closed-Cell Structure: Prevents water absorption and maintains integrity under pressure, with compressive strength up to 3.5 MPa for deep-sea resilience.

Corrosion and Hydrolysis Resistance: Chemically inert PVC formulation withstands saltwater, UV exposure, and biofouling, extending service life in marine environments.

CNC Machining Precision: Tolerances of ±0.1mm enable intricate shapes like syntactic foam hybrids or tapered buoyancy blocks, compatible with composite lamination.

Thermal Stability: Operates from -60°C to +70°C, with low thermal conductivity (0.03 W/m·K) for insulated subsea housings.

Eco-Friendly and Lightweight: Reduces overall vehicle weight by up to 40% compared to traditional foams, supporting sustainable marine exploration.

Density Grades: From P45 (lightweight buoyancy focus) to P250 (high-pressure structural).

Surface Treatments: Perforated or grooved for enhanced resin bonding in sandwich composites.

Dimensions: Up to 600mm thickness; custom panel sizes for large ROV frames.

Our marine structural foam core excels in demanding subsea scenarios, where reliability under pressure is paramount. As a PVC foam core specialist, we support:

ROVs and AUVs: Custom rov buoyancy foam blocks provide stable flotation and trim adjustment, enabling extended missions in oil & gas inspection or oceanographic research. For instance, in pipeline surveys, our closed cell PVC foam maintains buoyancy at 1,000m depths without compression failure.

Marine Platforms and Buoys: Used in offshore wind turbine floats or sonar buoys, offering vibration damping and impact resistance for wave-exposed structures.

Subsea Equipment: Buoyancy modules for underwater cables, sensors, and drones, where low water absorption ensures zero buoyancy drift over years of deployment.

Oceanographic Tools: Lightweight cores for gliders and profilers, optimizing energy use in long-duration environmental monitoring.

No Minimum Order Quantity (MOQ): We accept prototype and small-batch orders.

Free Samples: Request a free A4 sample to validate the material.

Fast Lead Times: 5-7 days for samples; 15-20 days for full container loads (FCL).

Global Shipping: We ship worldwide with customized packaging to ensure safe delivery.

As a core foam manufacturer with over 15 years in PVC foam innovation, UNION delivers premium marine structural foam at 25% lower costs than competitors. Our StruCell® line ensures batch consistency through rigorous testing, while tailored solutions—like custom density matching for your ROV design—meet exact engineering needs. Trusted by global clients in subsea tech, we combine expertise in polymer science with reliable supply as your PVC foam supplier.

| Product | Description | |

| P60, density 60kg/m³ | Density 60kg/m³, ideal for balanced buoyancy in shallow to mid-depth ROVs. Thickness: 2-80mm Plain size: 2450mm*1130mmProcessed size: 1220mm*1130mm | |

| P80,density 80kg/m³ | Density 80kg/m³, enhanced strength for AUV frames. Thickness:3-70mm Plain size:2180mm*1020mmProcessed size:1080mm*1020mm | |

| P100, density 100kg/m³ | Density 100kg/m³, high compressive resistance for deep-sea operations. Thickness: 5-45mm Plain size:2050mm*950mmProcessed size:1020mm*950mm | |

| P130, density 130kg/m³ | Density 130kg/m³, suited for heavy-payload subsea equipment. Thickness: 5-55mm Plain size:1900mm*850mmProcessed size:950mm*850mm | |

| P200 | Density 200kg/m³, maximum durability for extreme pressure environments. | |

ISO 9001

ISO 14001

RS Certification

TAK00001DV

RoHS

Flame Retardant Report

Order Confirmation

Production (CNC Machining)

Quality Control (Batch Testing)

Packing (Protective Nesting)

Delivery (Global Shipping)

After-Sale Support

No MOQ; Free A4 Samples; Lead Time: 7-10 days for prototypes, 20-25 days for bulk.

|

Q1: What makes StruCell® rov buoyancy foam superior for deep-water ROV applications?

A: Our closed cell PVC foam offers unmatched hydrostatic resistance, with densities calibrated to prevent compression at depths exceeding 4,000m. This ensures stable buoyancy without added weight, unlike open-cell alternatives that absorb water and fail under pressure.

Q2: How does your CNC machining process work for custom marine structural foam core shapes?

A: We use large-bed CNC routers to mill precise buoyancy modules from your CAD files. Components are shipped nested in panels with breakaway tabs for protection, allowing easy extraction and integration into your assembly—ideal for ROV manufacturers seeking efficiency.

Q3: What's the best density for AUV buoyancy modules, and how do I select it?

A: For most AUVs, P80 or P100 provides optimal stiffness and buoyancy. Factors like operational depth and payload dictate the choice—our team, as an experienced PVC foam manufacturer, can simulate buoyancy models to recommend the right marine structural foam core.

Q4: Do you offer testing or samples for compatibility with my subsea composites?

A: Yes, free A4 samples of our PVC foam core are available to evaluate resin adhesion and performance. This helps confirm compatibility before bulk orders, ensuring your project succeeds without surprises.

Q5: How does your closed cell PVC foam handle long-term marine exposure?

A: With <0.5% water absorption and anti-hydrolysis additives, it resists degradation in saltwater for 10+ years. As a reliable PVC foam supplier, we back this with real-world case studies from offshore deployments.

Why Union Composites Stands Out as a Leading PVC Foam Manufacturer for Marine Structural Foam Core

Custom-Shaped Structural PVC Foam for Marine Applications | High-Performance Buoyancy Solution

Optimizing Catamaran Tunnel Design with V-Groove Scrim Board PVC Foam

Why PVC Foam is the Best Core Material for Campervan Conversions?

Alternatives to Marine Plywood: Why Structural PVC Foam Core is Revolutionizing Boat Building

Solving customs clearance problems for German wind power customers